media coverage

1. From "Once-Through" to "Circulating" - The Evolution of Water Use

What Is a Circulating Water System?

In simple terms, a circulating water system is a closed or semi-closed loop in which water, after being used, is cooled, treated, and returned for the same purpose.

-Once-Through Water System (Single-Pass Use)

Heated water from industrial equipment or HVAC chillers is discharged directly into the drainage system, while fresh water is continuously supplied for cooling. This extensive and linear approach consumes large volumes of water and releases significant waste heat and wastewater.

- Circulating Water System (Water Reuse)

Instead of disposal, heated water is returned to the system and cooled through cooling towers or similar equipment, then pumped back for reuse. Water continues to "work" within the loop, requiring only minimal makeup to compensate for natural losses.

Switching from Once-Through to Circulating Is a Strategic Upgrade

It represents a fundamental shift - from resource-intensive operations to efficient, sustainable water management.

Three Core Advantages

1) Exceptional Water Savings

This is the greatest value of circulating systems - reusing water dramatically increases utilization efficiency. Well-designed systems can achieve over 95% water savings.

2) Significant Energy and Cost Reduction

Reusing water also retains the thermal energy it carries. Compared with repeatedly heating or cooling fresh water, circulating systems significantly reduce energy demand and operating costs.

3) Operational Stability & Environmental Protection

Circulating systems maintain stable water temperature, pressure, and flow - ensuring reliable industrial and HVAC performance. At the same time, they greatly reduce wastewater discharge and thermal pollution.

2. How Does the System Work?

Circulating water systems generally fall into two categories - open-loop and closed-loop - each with distinct operating mechanisms and management priorities.

- Open-Loop Circulating Water System

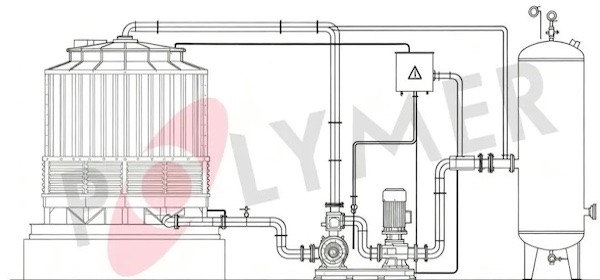

At its core, the system consists of pumps, heat exchange equipment, and a cooling tower forming a continuous loop.

Operating Principle:

Cold water flows through heat exchangers - such as condensers or reactor jackets - absorbing process heat and becoming warm. Pumps then deliver the heated water to the top of the cooling tower. Inside the tower, the water is evenly distributed and fully contacts upward-moving air. A small portion evaporates, removing heat and cooling the remaining water. The cooled water collects in the basin and is pumped back to the heat exchanger, starting a new cycle.

Key Characteristics:

Water is exposed to air, resulting in evaporation loss;

Simpler design and generally lower installation cost;

Requires careful control of water quality, volume, and makeup water.

- Closed-Loop Circulating Water System

Water circulates within sealed piping or coils, isolated from the atmosphere.

Operating Principle:

The circulating water transfers heat through a heat exchanger - such as a plate exchanger - where an external cooling medium (water or air) removes the heat. Because it is sealed, evaporation loss is minimal and water quality remains stable over time.

Key Characteristics:

Higher water efficiency with minimal makeup water;

Significantly reduced corrosion, scaling, and biological fouling;

Higher initial cost and potentially lower heat transfer efficiency than open systems.

3. What Are the Core Parameters?

The stability of a circulating water system relies on accurately compensating water losses and effectively controlling water concentration. Therefore, system monitoring and management should focus on five essential parameters.

- Circulating Water Flow Rate (R)

The volume of water flowing through the system per unit time (m³/h), reflecting system capacity and thermal load. It influences heat exchange performance, pump selection, and operating energy consumption.

- System Holding Volume (V)

The total static water volume stored within the system (m³), serving as its hydraulic buffer. Insufficient volume may cause fluctuations in water quality, shorter chemical retention time, and unstable operation.

- Cycles of Concentration (K)

The most critical indicator in circulating water management. Defined as the ratio of the concentration of a non-scaling, non-volatile substance (commonly Cl⁻ or K⁺) in circulating water to that in makeup water. A higher value indicates greater water reuse efficiency.

- The Three Main Water Losses

Evaporation Loss (E): Water evaporates in the cooling tower, removing heat - this is the primary cooling mechanism.

Drift Loss (D): Water droplets carried out by exhaust airflow, reducible through drift eliminators.

Blowdown Loss (B): Controlled discharge used to regulate cycles of concentration and remove accumulated impurities.

- Makeup Water Requirement (M)

Fresh water added to compensate for evaporation, drift, and blowdown losses.

Fundamental Equation: M = E + D + B

4. What Balances Cost and Risk?

The cycles of concentration (K) is the most critical operational control index in a circulating water system, and its value directly shapes overall system performance.

- Water-Saving Performance

A higher K value means water is reused more times within the system, reducing makeup water (M) demand and enhancing water efficiency. Increasing K from 1 (equivalent to once-through water use) to 5 can reduce makeup water by approximately 95%.

- Economic Benefits

As K increases, both makeup water expenses and blowdown treatment costs decrease, lowering operating expenses. However, benefits diminish beyond a certain threshold - additional increases in K yield smaller water and cost savings.

- Operational Risks

A higher K also concentrates scale-forming ions (e.g., calcium, magnesium) and corrosive ions (e.g., chloride, sulfate). This dramatically increases the potential for scaling and corrosion.

Additionally, warmer water and nutrient accumulation create favorable conditions for microbial growth, including Legionella.

Managing K Is a Strategic Balancing Act!

5. How to Ensure Long-Term Operation?

In essence, the core mission of circulating water management is to establish and maintain an optimal cycles-of-concentration value through controlled blowdown. However, in real-world operation, managing K alone is not sufficient - water treatment programs and chemical conditioning are also required to protect the system. The objective is to maximize water savings while keeping scaling, corrosion, and microbial growth risks within acceptable limits.

Becoming proficient in circulating water management requires more than understanding system principles, mechanisms, and key parameters - it also demands recognizing that cycles of concentration and water treatment programs are interdependent and inseparable. Only with disciplined, data-driven, and refined management can circulating water systems operate in a manner that is sustainable, reliable, efficient, and economically over the long term.