media coverage

Limestone-gypsum wet flue gas desulfurization system,1# Desulfurization system is two furnaces and one tower, 2# Desulfurization system is one furnace and one tower. When the SO2 concentration of the desulfurization inlet is about 1000 mg/Nm3, the outlet SO2 concentration will rise to about 50 mg/Nm3. 1# desulfurization and 2# desulfurization systems are equipped with three circulating pumps.

It is necessary to increase the sulfur content of raw materials by 20~30%, that is, the inlet SO2 concentration is increased from 1000mg/Nm3 to 1200mg/Nm3, and the export SO2 emission is ensured not to exceed the standard.

Application

Stage 1: Add desulfurization synergist, stop a slurry circulating pump, increase the sulfur content of the inlet and observe the desulfurization efficiency.

Stage 2: Three slurry circulating pumps are operated at the same time, increasing the inlet sulfur and observe the limit value at which the sulfur can be increased.

Operational Results

Stage 1:Comparative Results

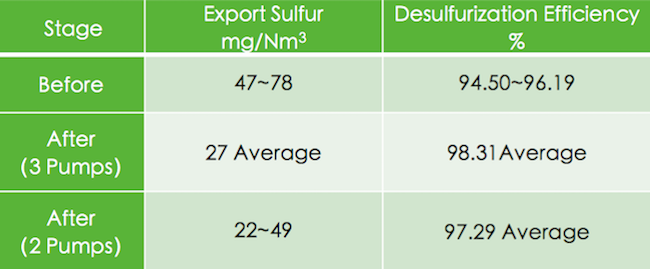

1# Desulfurization System

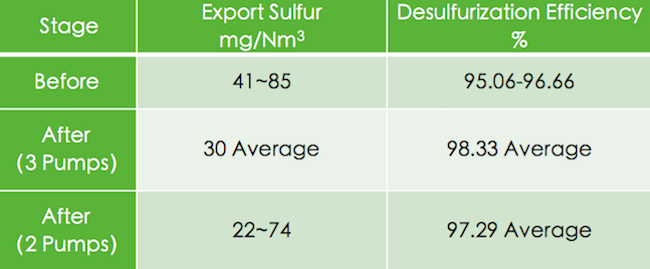

2# Desulfurization System

The above data shows that after the addition of the desulfurization synergist, the sulfur content of the desulfurization system is significantly reduced.

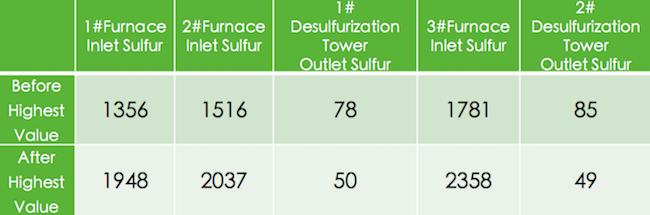

Stage 2: Comparative Results

Unit:mg/Nm3

From the above operational data, it can be seen that under the operation of the three pumps, the maximum sulfur content of the inlet is increased by 32-44%, the desulfurization system can operate stably, and the sulfur output can still meet the standard discharge.

Benefits

1- Control the export of SO2 through POLYMER desulfurization synergist, so that high-sulfur ore raw materials can be used, which greatly reduces the procurement cost of iron ore raw materials.

2-When the average sulfur content of the inlet is lower than 1700 mg/Nm3, a circulating pump can be shut down, which can save a lot of electricity bills.POLYMER’s Desulfurization Synergist