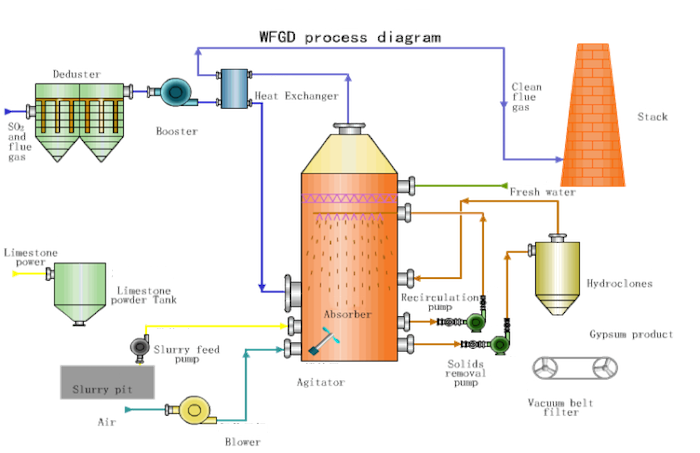

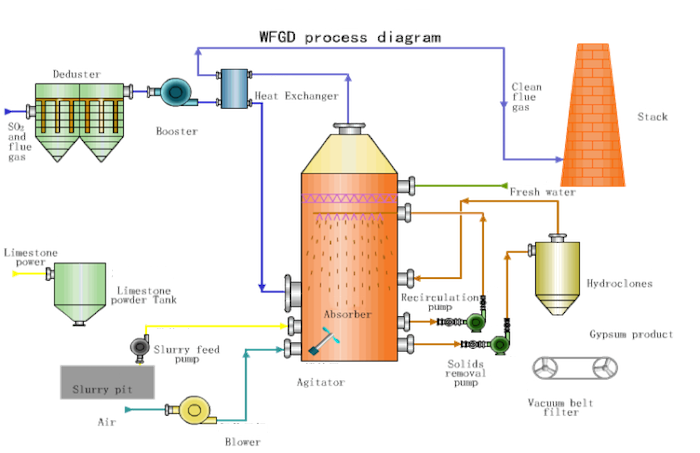

First, look at

the limestone - gypsum wet flue gas desulfurization process.

The biggest

one above is the desulfurizer tower

It does a lot

of work

Industrial

processes release a lot of SO2, which is absorbed in the

desulfurizer tower

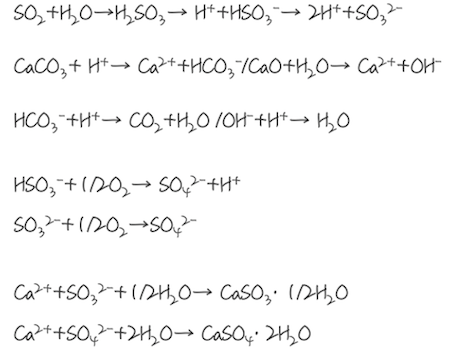

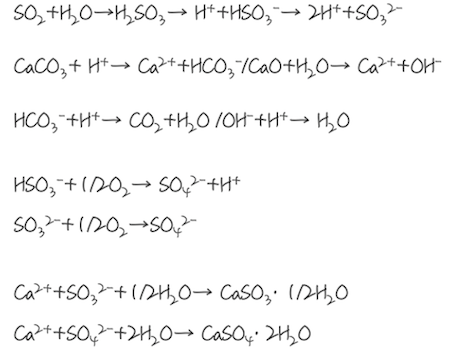

Reaction Steps

So you don't

have to worry about SO2 emissions

When you're

relaxing

The

desulfurization tower is covered with calcium sulfate and calcium carbonate, its

tray and nozzle went out of action

The function of scale inhibitor is

1. Increase the solubility of scaling compounds

The organic

acids and polyelectrolytes in the scale inhibitor disassociate in water, and

form negatively charged molecular chains. The molecular chain and Ca

2+,

Mg

2+ form stable complex, thereby increasing the solubility of CaSO

4 in water.

2. Lattice distortion theory

CaSO

4 crystallization is strictly in accordance with the order.

The organic

acids in the scale inhibitor will chelate with Ca

2+, inhibiting the

sequential growth of the lattice, making the lattice distorted and difficult to

grow.

In addition,

organic acid surface active agent molecules are involved in lattice growth,

lattice dislocation, the formation of some holes, making the scale soft.

3. Electrostatic repulsion

Polyelectrolytes

have strong adsorbability after ionizing in water. They will adsorb CaSO

4 small crystal, dust, sediment, etc., and change the charge distribution on the

particle surface to form a double electric layer, thus preventing the collision

of CaSO

4 small crystal to form a large crystal, and preventing the

collision with the metal heat transfer surface to form a scale layer.

POLYTE® 507A

is an excellent scale inhibitor and can be use in desulfurization tower system

to prevent fouling.