media coverage

SO2 is one of the most common and irritating sulfur oxides, one of the major pollutants in the atmosphere. The gas is emitted when a volcano erupts,

and sulfur dioxide is produced in many industrial processes, a colorless gas with a melting point of -75.5 °C.

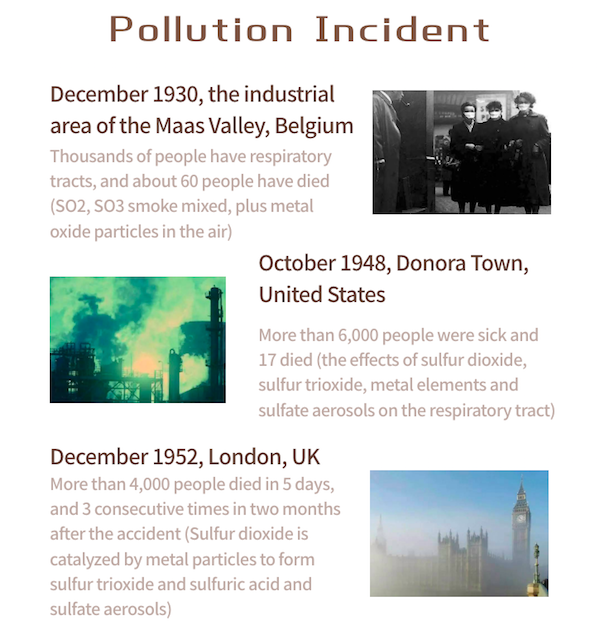

Look at a set of data firstly

Look at the second set of data

Here comes the solution for SO2

The desulfurization synergist, also known as the desulfurization catalyst, is mainly composed of a polymer catalyst which has strong reactivity against SO2.

In the WFGD, the addition of the desulfurization synergist can greatly improve the desulfurization efficiency and significantly reduce the sulfur dioxide emission concentration.

1-Disperse and promote limestone dissolution

The desulfurization synergist can weaken and eliminate the double membrane effect, change the wettability of the solid-liquid interface, disperse and promote the dissolution of limestone, and accelerate the reaction speed.

2-Improve desulfurization efficiency and reduce outlet SO2 concentration

At the gas-liquid interface, the desulfurization synergist can combine the large amount of H + ions generated by the SO2 dissolution, so that the H + ions are transferred from the liquid film to the liquid phase body, and the pH of the slurry does not fall too fast due to the dissolution of SO2, while the gas phase resistance Reduce and promote SO2 absorption.

POLYTE® desulfurization synergist can increase the desulfurization efficiency by 2~3% and rapidly reduce the concentration of SO2 in the outlet by 30%-50%.

3-Saving plant power consumption rate

Under the premise that the concentration of sulfur dioxide in the desulfurization device is within the design value range, after adding the desulfurization synergist, on the one hand, part of the absorption tower slurry circulation pump can be stopped to reduce the power consumption rate of the desulfurization system; on the other hand, the pulping system can be saved. The energy consumption of the ball mill can effectively improve the utilization rate of coarse-grained limestone (250 mesh), and basically achieve the same desulfurization efficiency as the (325 mesh) particle size limestone.

POLYTE® Desulfurization Synergists reduce the plant power usage by 0.1%-0.2%.

4-Improve the sulfur adaptability of coal combustion

The desulfurization synergist is added to the desulfurization system to greatly improve the desulfurization efficiency, and the sulfur content of the coal can be increased under the premise of ensuring the same sulfur dioxide concentration at the outlet.

POLYTE® Desulfurization Synergists increase the system's suitability for coal sulfur by 20%-50%.